ABOUT US

We started our activity in 2006 from where we are in a constant growth and development until today, we have always focused on the design and manufacture of all kinds of industrial projects, among which the progressive precision molding, injection molds in general and control instruments for production.

Global Outsourcing is the trademark of our company Shanghai Helong International Trading Co., Ltd. located in China.

Our production center is in Kunshan with more than 2,500m2 of facilities.

Our offices and control center are in Changzhou where we coordinate and direct the execution and development of all our projects.

Our goal is to provide our clients with finished projects with the highest quality and performance, thus allowing a high profitability and a short amortization period.

QUALITY POLICY

Our goal: THE TOTAL SATISFACTION OF OUR CUSTOMERS

The Outsourcing Global technical department has specialized and highly qualified personnel, we have many years of experience in the field. Throughout our short but intense history, we have developed and manufactured die-casting solutions and molds for the manufacture of complex parts as well as parts and electrical / electronic parts of the automotive industry mainly … always meeting the most demanding requirements of our customers in terms of quality, service and delivery time.

To provide you with the highest quality projects possible, our technical staff is always ready to offer advice and collaboration with our customers always, from the initial stage of development, to the design of the part or parts to be produced up to the final stages of the project.

Everything starts with the plan of what needs to be done, the production requirements and other initial aspects to begin the study of the project and the realization of a preliminary layout where the steps of the manufacture of the piece to be produced are studied, to optimize all parts that make up the project.

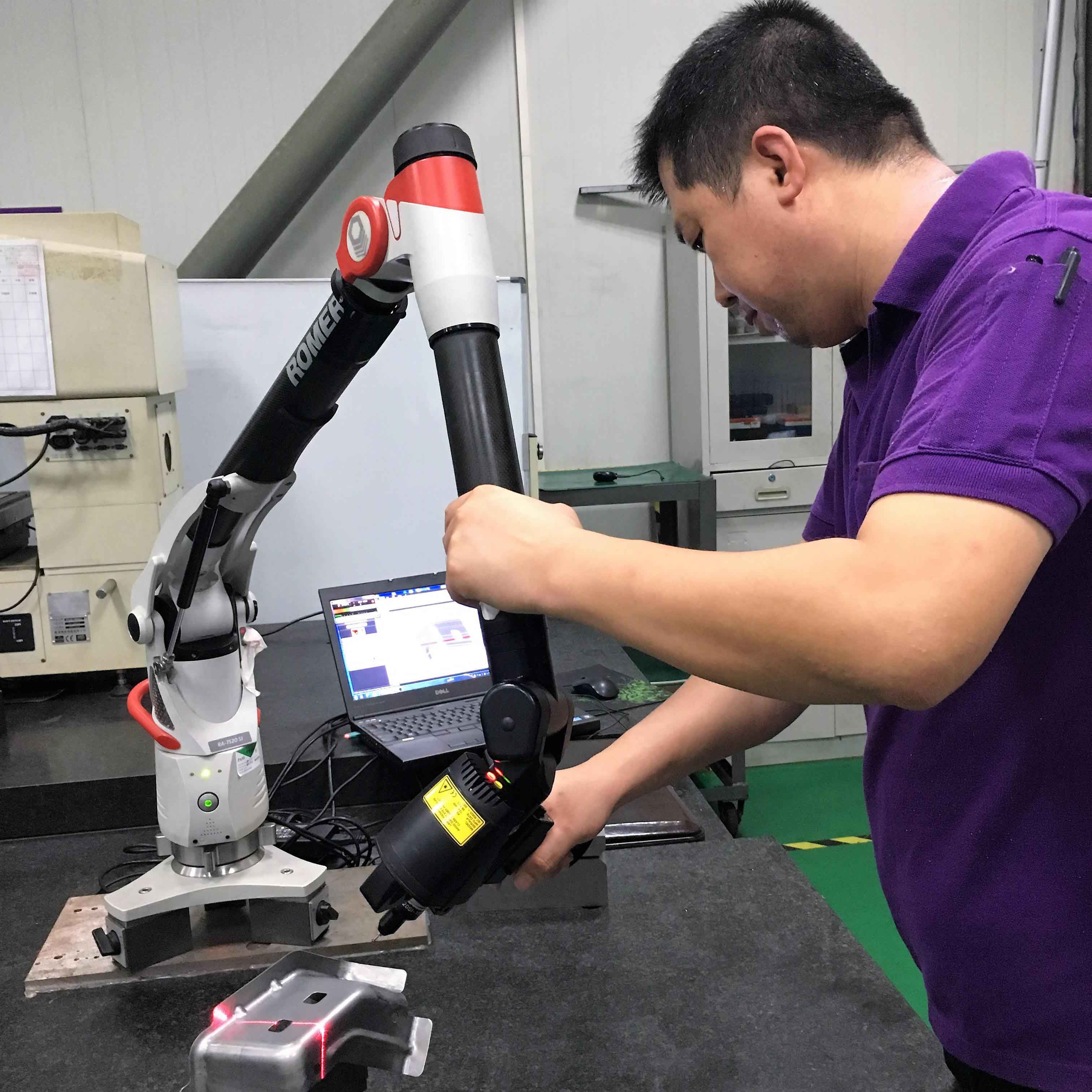

Throughout this process our company uses CAD / CAM / CAE workstations with the latest technological advances and state-of-the-art equipment.

QUALITY CRITERIA

The quality criteria form an essential part of our thoughts and actions, to achieve a general and comprehensive quality culture at all levels and areas of our company.

Our commitment is total quality as a method to strengthen the relationship with all our customers.

We carry out strict three-dimensional controls, to be able to verify the parts and comply with all the dimensional requirements established for the project.