In Outsourcing Global we work for the most demanding sectors of the market in the manufacture of parts and components of the automobile industry, electrical, electronic and other components.

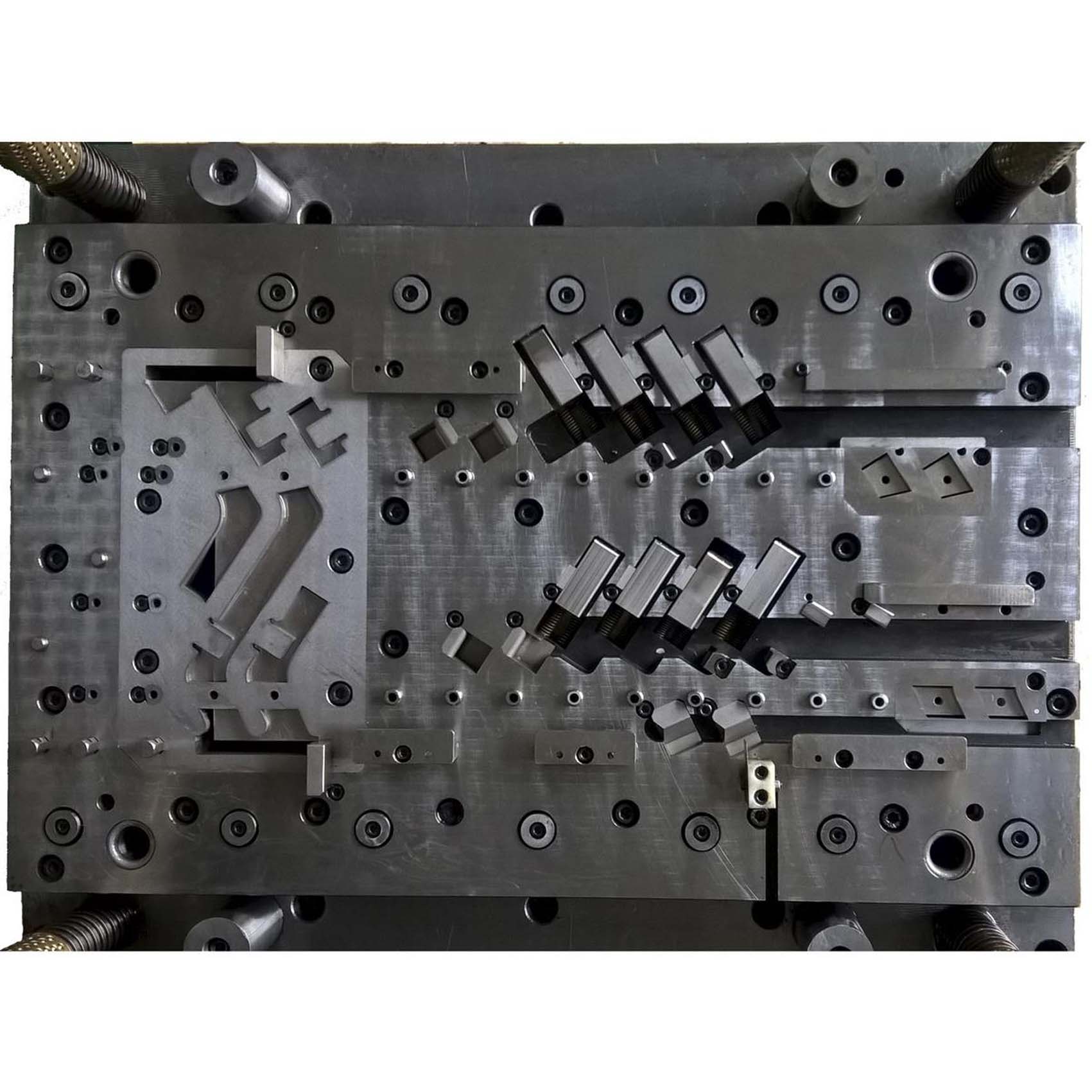

We build all types of progressive dies and/or phased dies.

Total involvement with the client to satisfy all your needs, with the personal treatment of a family business. Another important aspect for us is the logistics quality, with tight deadlines to be more competitive.

We offer a complete service for your projects. Working hand in hand with engineering design and development projects, as well as follow-up on the subsequent manufacturing.

Send us samples or drawings CAD and / or 3D, so that we can offer study and quote of the projects from the design to the final manufacture.

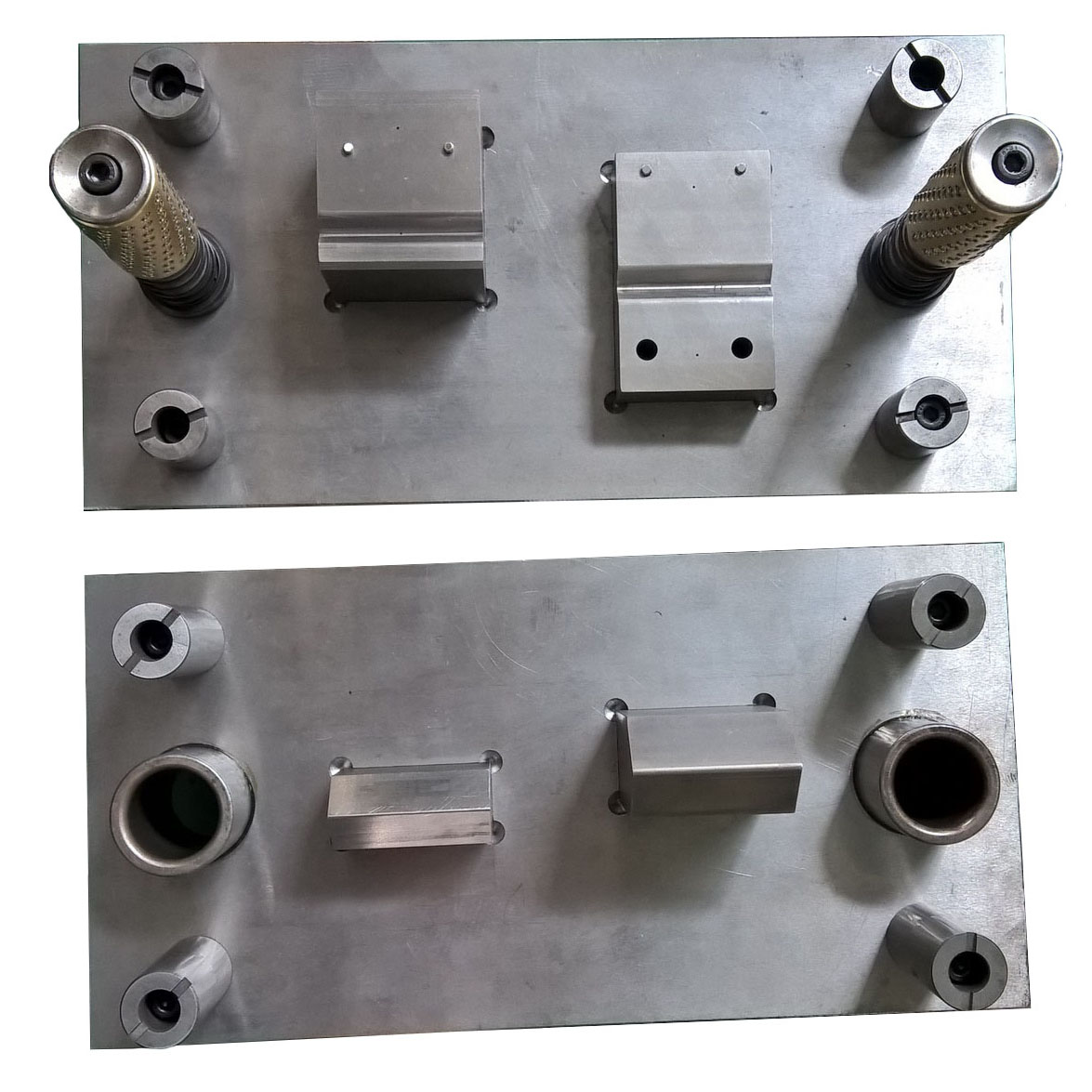

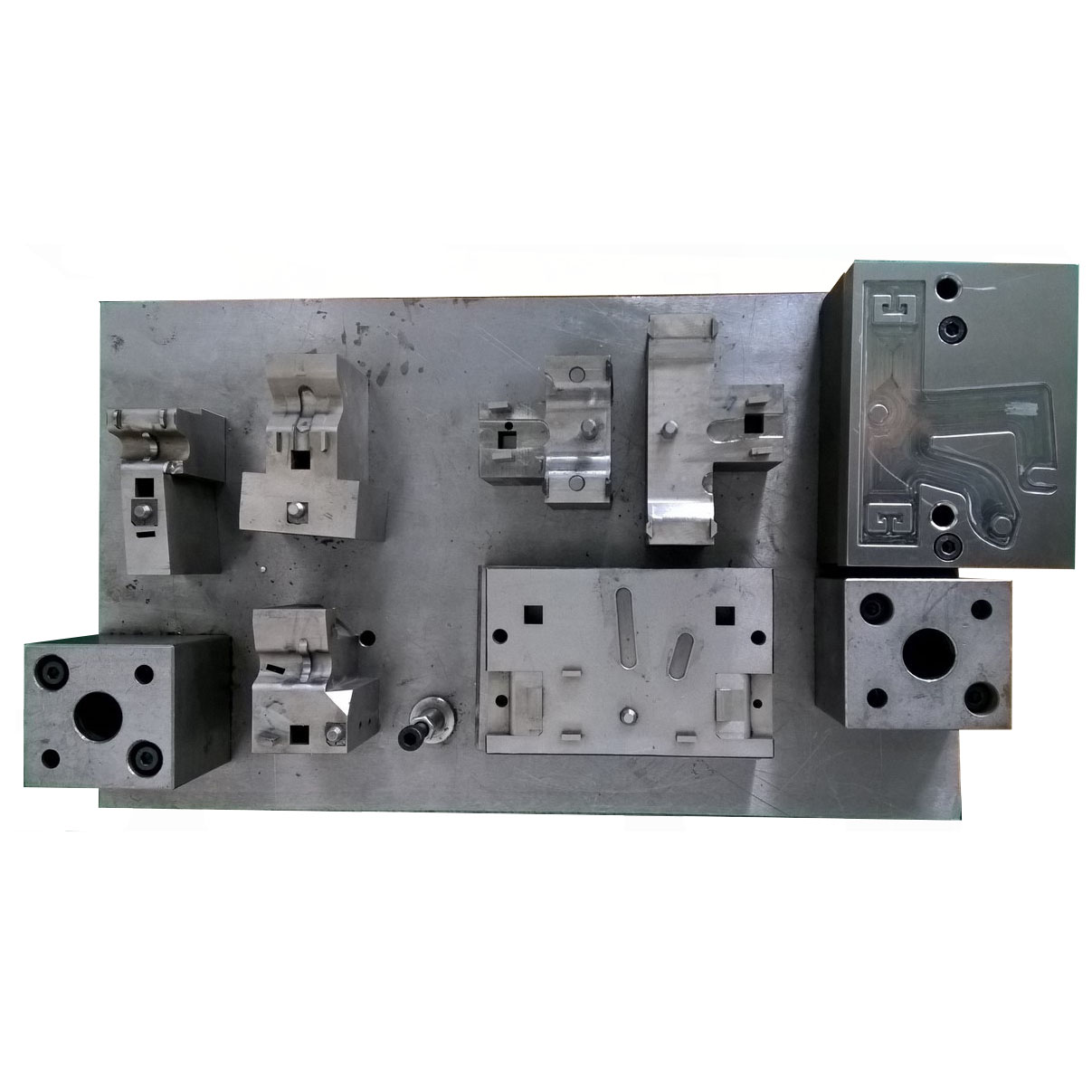

PRECISION DIE TOOLING

With almost 10 years of experience manufacturing of stamping dies, progressive dies and stamping molds are one of our main activities, we have grown to be recognized as an important ally for our customers. Our main projects are for the manufacture of progressive dies of high production.

We carry out projects of progressive dies for presses of powers up to 800Tn.

We work with all kinds of metals; Steel, aluminum, bronze, brass, copper, stainless steel in measurements ranging from 0.1 mm to 10 mm.

Our main business sectors are in these areas:

- Automotive industry.

- Electrical / electronic.

- Machinery in general.

- Urban furniture.

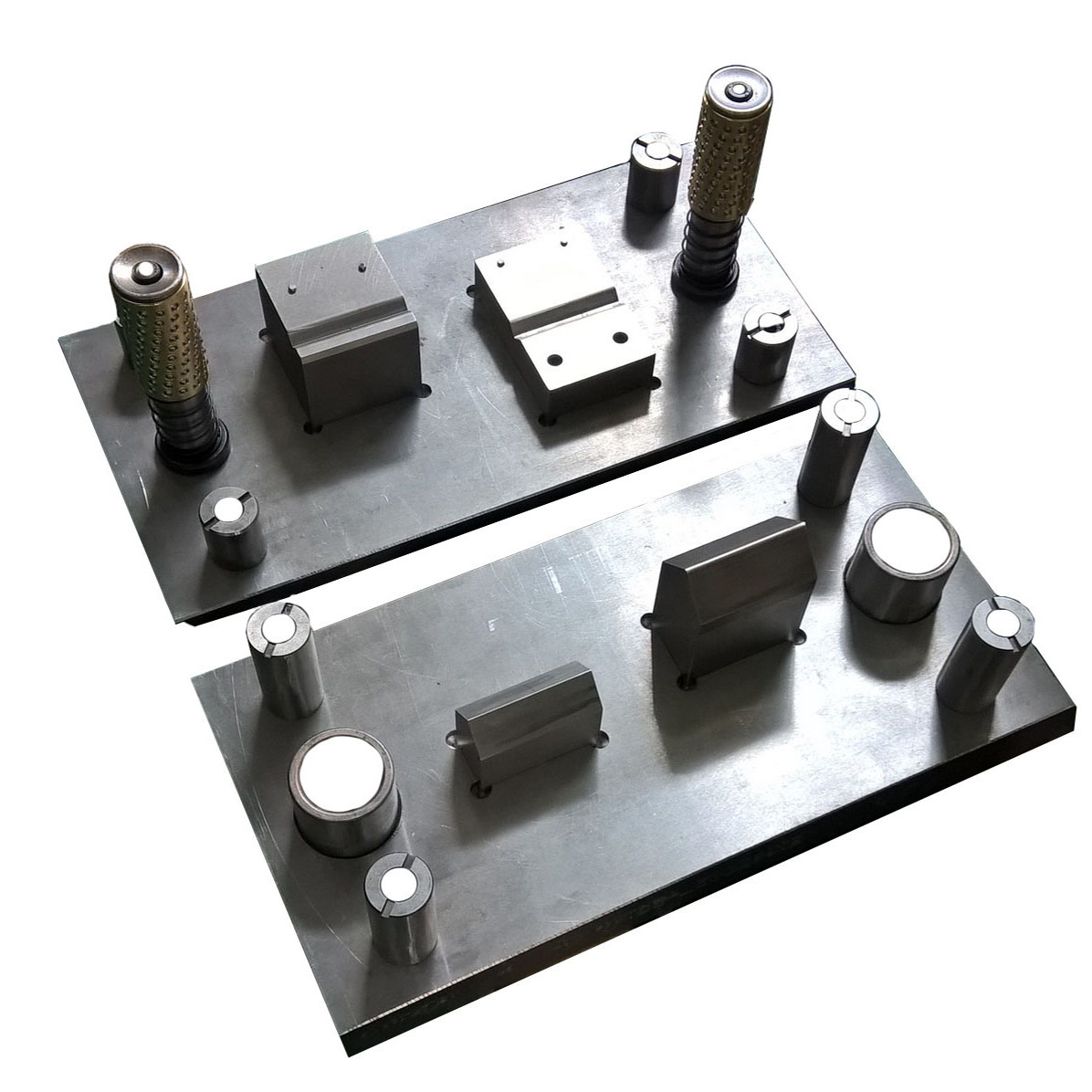

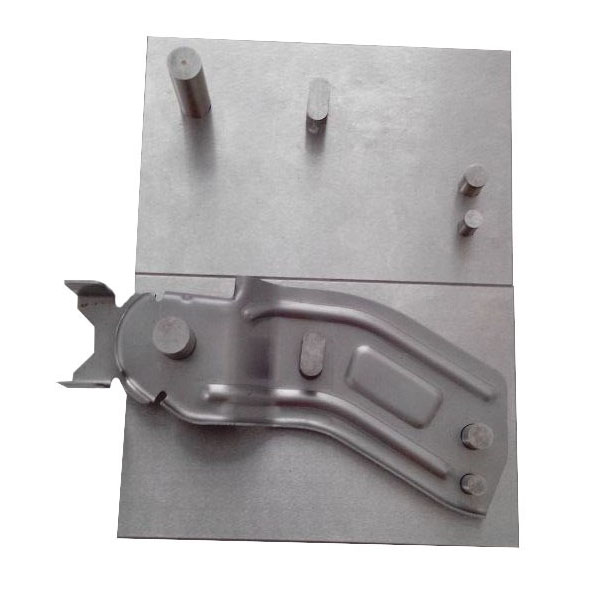

PROTOTYPE CREATION

Prototypes in general:

Before the production of a progressive die, or as a study of a new project, we can make basic tools for the manufacture of prototypes with the quality of finish that would have the final pieces of progressive die, to check that the piece accomplishes the purpose for which it was designed.

We can make prototypes of any material and design that you need an industrial production.

CNC machining and turned parts:

We make all kinds of special pieces on flat, all kinds of materials, carbon steel, stainless steel, brass, aluminum, technical plastics and other materials.

We can also perform the surface treatment you need.

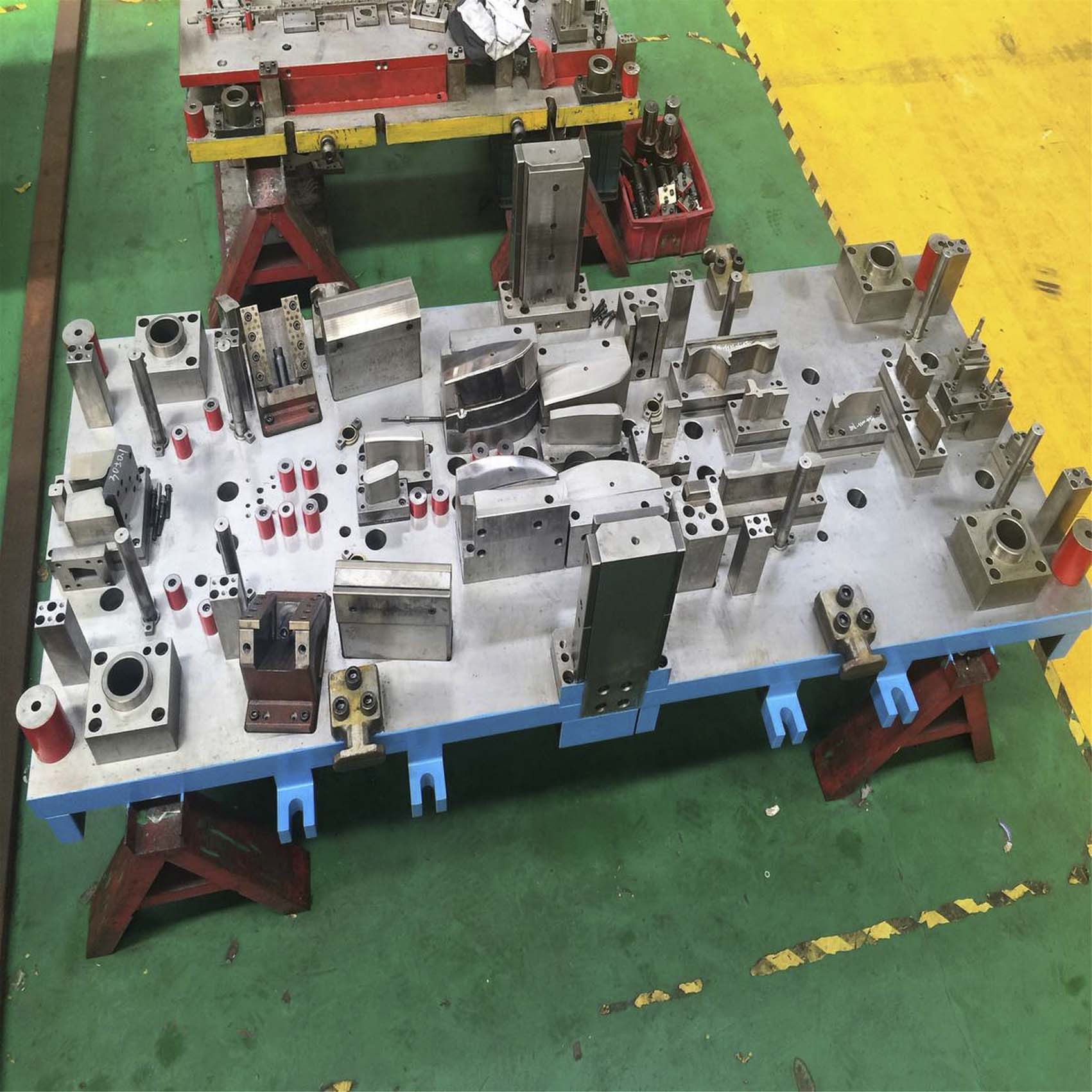

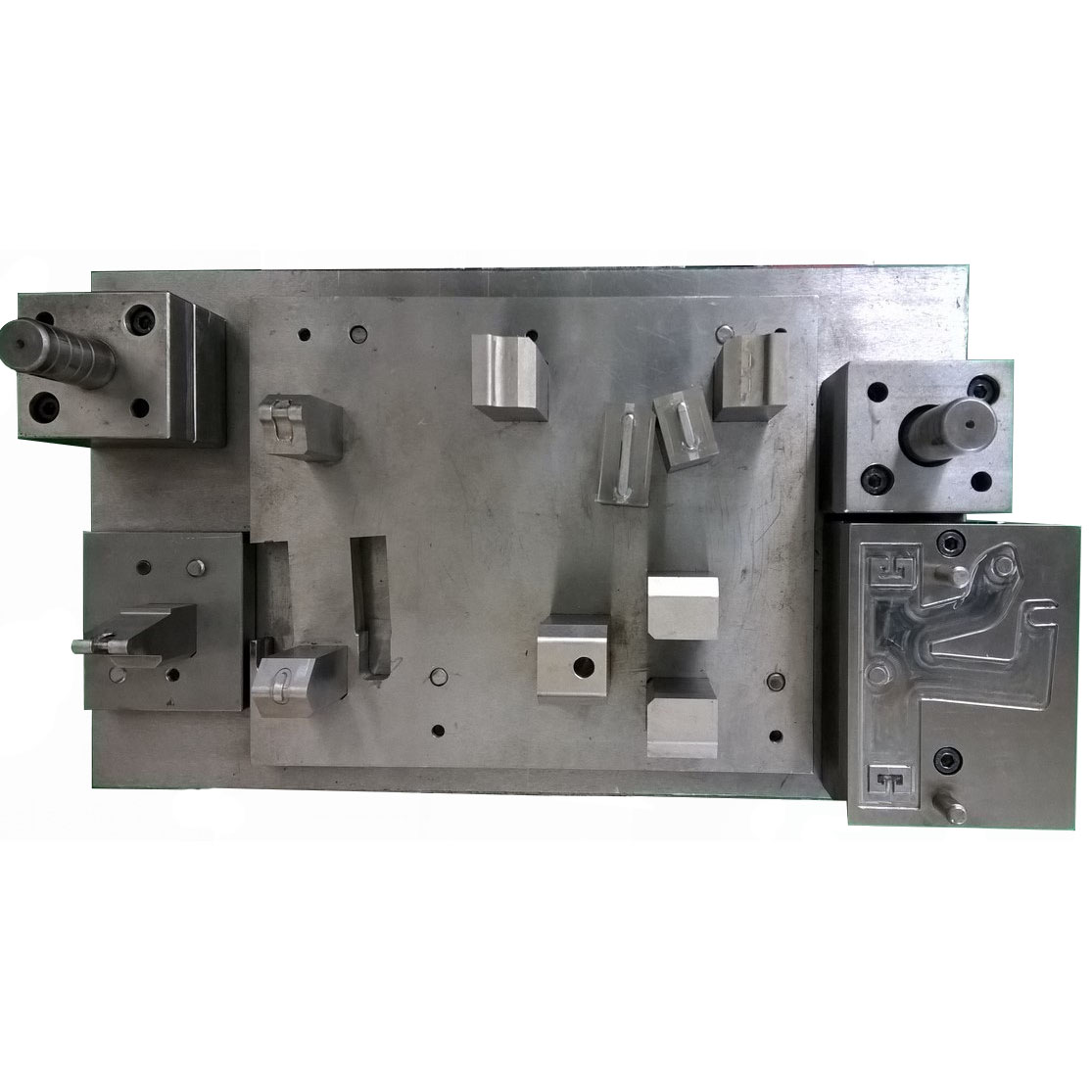

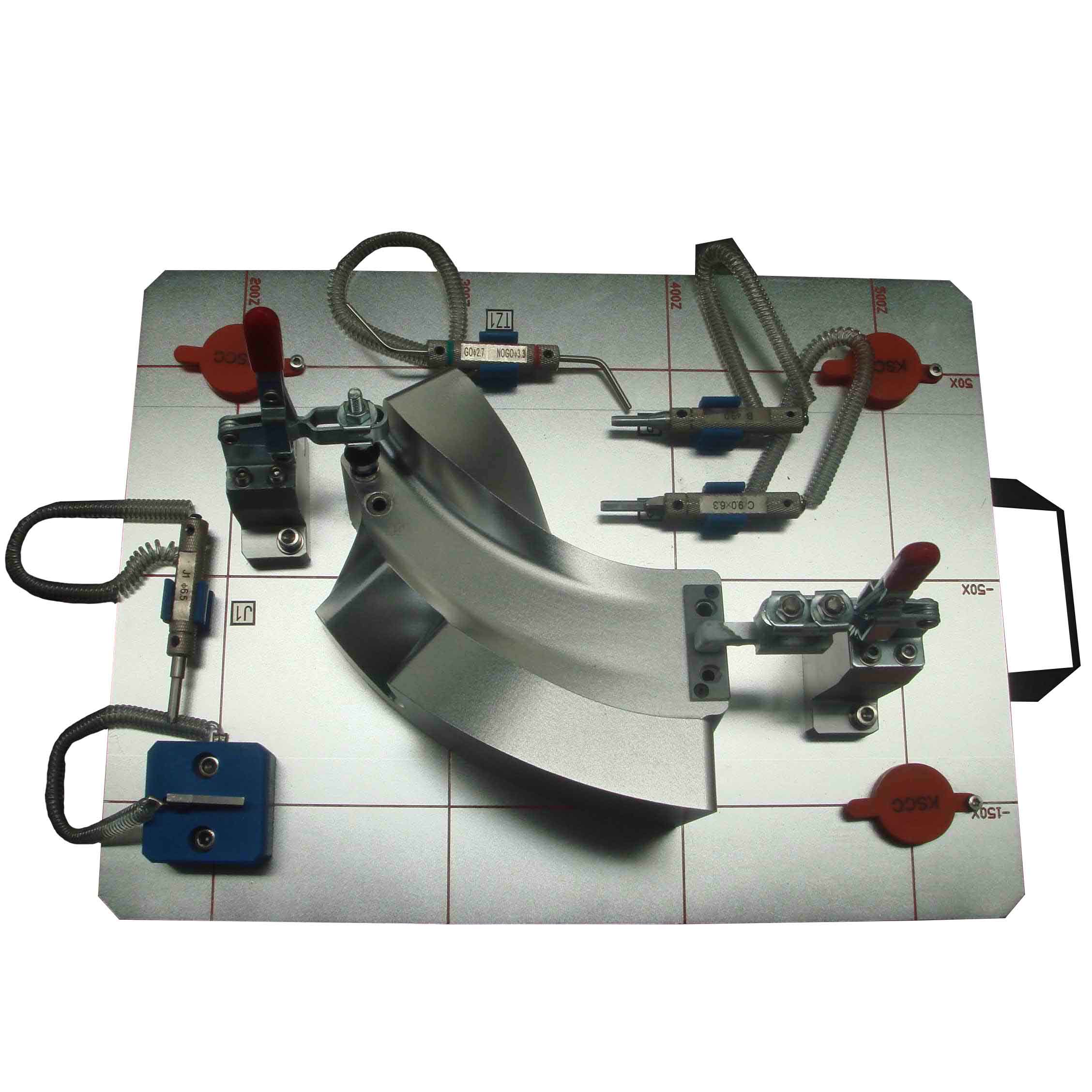

PRODUCTION CONTROL TOOLS

Checking fixtures.

We have this production mainly for our customers in the automotive sector, meet all the requirements of automotive companies.

With each of these checking fixtures made, we do a detailed report of the 3D verification of all control parts.

General dimensions control tools.

They are intended for the control of the production of the parts of the pieces with measures of great importance for their functionality

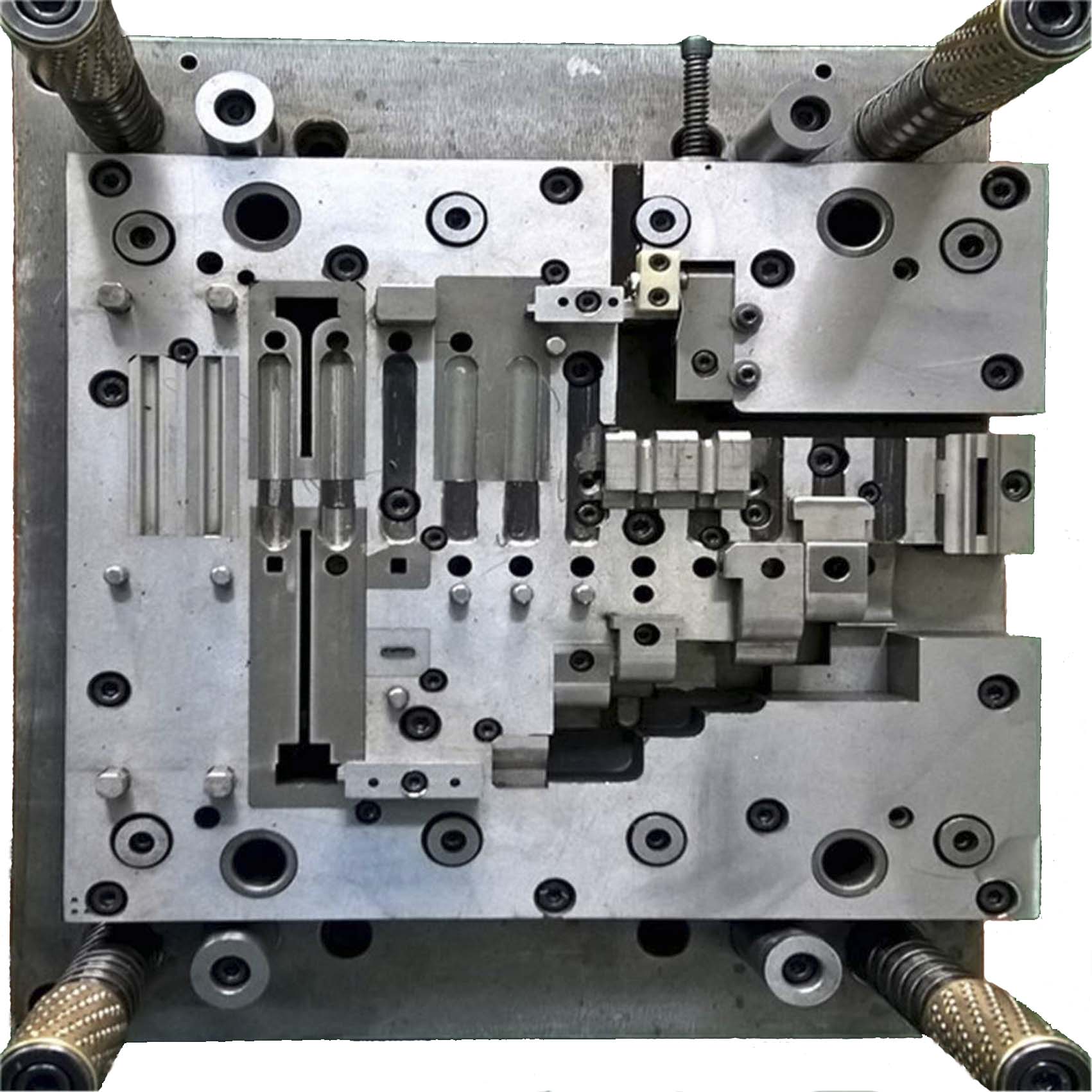

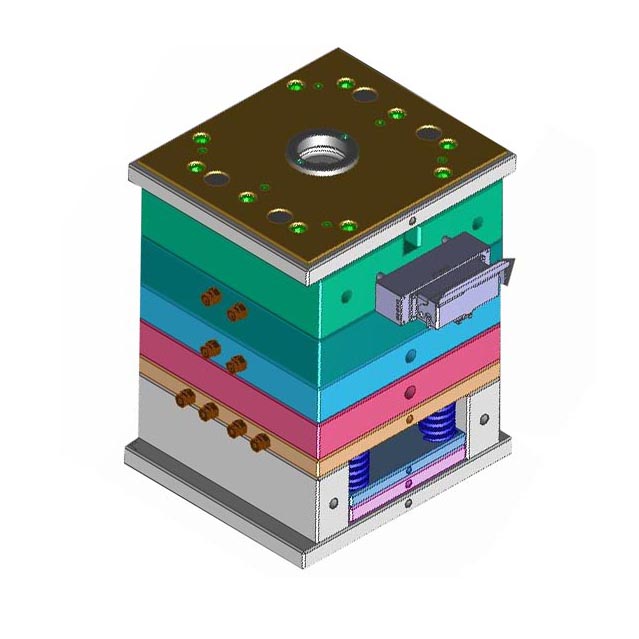

INJECTION MOLDS

We focus on projects of thermoplastic injection molds and non-ferrous metals.

High quality materials and an optimized development of the refrigeration, precision machining and a total control of the process is what allows us to offer efficient and competitive molds to get the high profitability of our clients.

Our main business sectors are in these areas:

- Electrical / electronic.

- Machinery in general.

- Urban furniture.

- Others.

We specialize in the injection of technical materials such as PC, PA, POM, PBT, ABS, PP, etc.

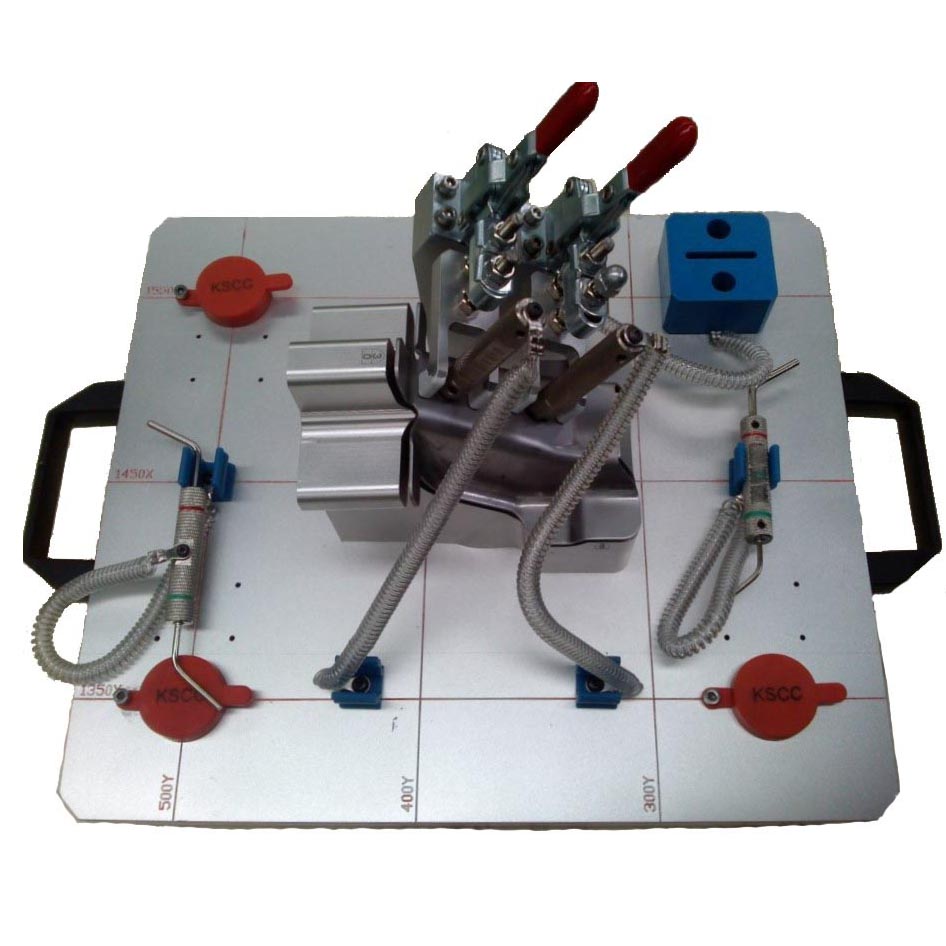

PRODUCTION AUTOMATIC SYSTEMS

Circular vibratory feeders

They are an excellent solution for the orientation of parts, however complex they may be. Very reliable in its operation

Main features:

- Compact design.

- Custom manufacture to the requirements of part design of feed speed.

- Excellent cost performance rate.

Linear vibratory feeders

They are used to feed parts that have previously been oriented by a circular feeder.

They are of correct application to transport pieces of almost any type, also they can be used to dose granulated product.

They can be manufactured in different lengths, between 400 and 5.000 mm.

Reload systems

We can make different types of refill lifting hoppers with capacities from 0.150 m3 to 1 m3

They maintain in a controlled way the recharge of parts in the feeders.

All parts in contact with the parts are made of stainless steel.

They have greater capacity of load than the vibratory hoppers and less requirement of recharge giving comfort and security to the operator.

Main features:

- Provide controlled recharge of parts to the feeders.

- Easy modification or adaptation.

- Variable and automated transport speed.

- Suitable for parts with simple geometry.

OUTSOURCING OF PROJECTS

We can make any partial production or service in what would be our common activities:

- Machining area.

- General EDM and wire cutting area.

- Welding robotic tools.

- Maintenance and repair in general.

In this way, our customers avoid increasing their company structure due to a specific increase in production or work. It is here that we bring all our resources with experienced and qualified personnel.

PRODUCTION SERVICE

If it is necessary to produce parts, pre-series or large series, make custom packaging and we can make the shipments where it is needed.